Journal Bearing Testers

We Have the Right Test Rig for your Testing Requirements!

Timelapse of journal bearing run-in

JBT1k

Plain bearings are ubiquitous in mechanical engineering and place high demands on control, regulation and measurement technology during development in order to precisely record the interaction between lubricant, bearing material and geometry.

JBT10k

For this reason, we not only have one plain bearing test rig, but also offer standard test devices for different contact pressure levels. All our radial plain bearing test rigs are equipped with suitable lubrication units, measurement technology and control software, have infinitely variable load and speed control and can be operated unidirectionally and oscillating up to the smallest swivel angles.

1

2

3

4

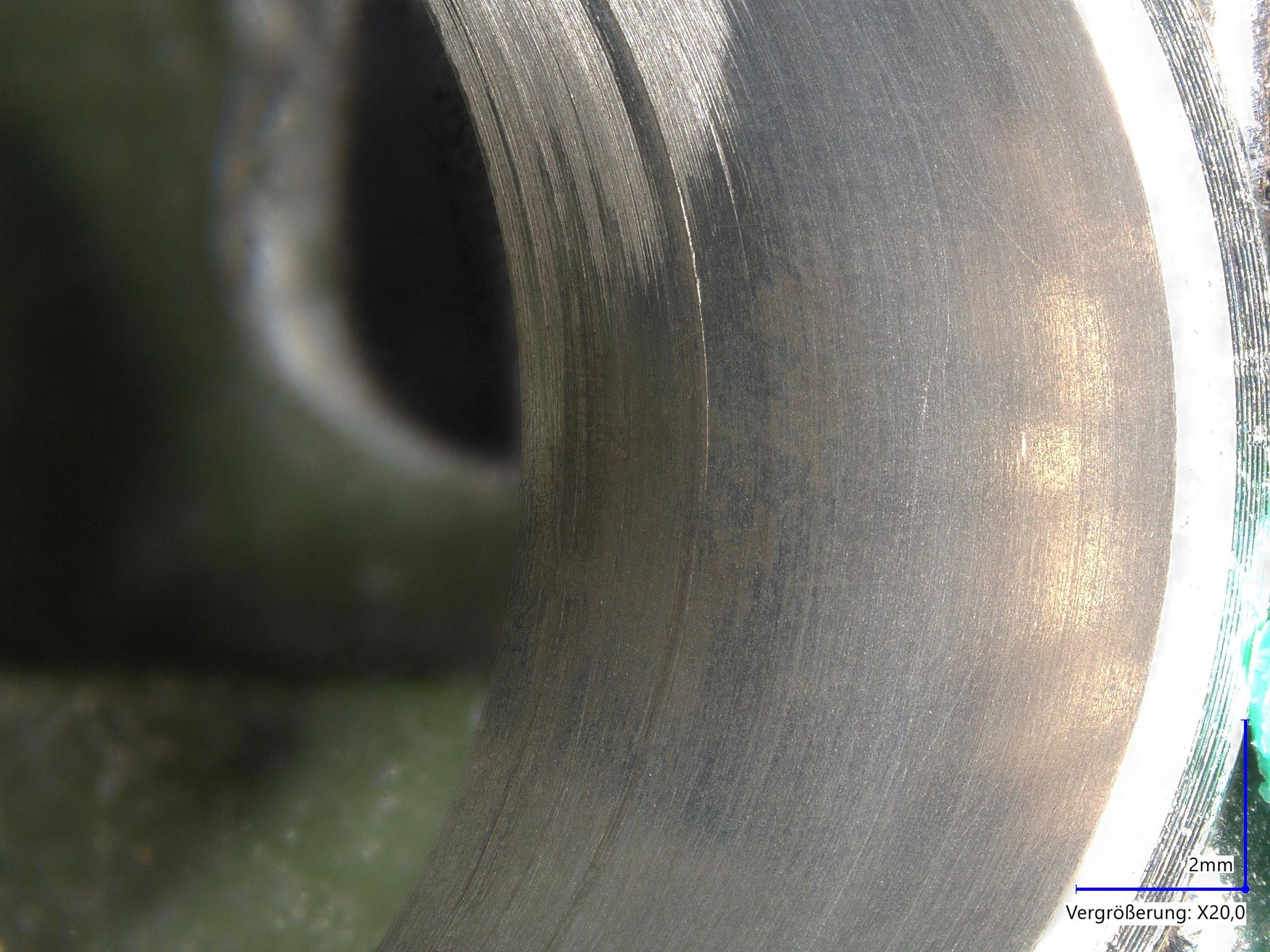

1: a fresh aluminium bearing, 2: one after a test with high-ref oil, 3: with low-ref oil, 4: after a lubrication deficiency run

Successive load and speed ramp cycles on the same bearing. The Acoustic Emission measurement allows the run-in between the cycles to be easily understood. The run-in is also visible in Contact Current, but also the fact that a lubrication gap can no longer form across the speed ramps in ‘DeficientLubricant’.

JBT60k

However, the ideal plain bearing test does not always come off the shelf. That's why we work with you to develop, design and manufacture your ideal plain bearing test rig with the right motorisation and load option, so that you always end up at the ideal operating point.