back to blog overview

Tribometry 4.0

Application-oriented tribological testing technology (tribometry) is a decisive development tool on the way to a high-performance product. Based on the tribological system analysis and the test strategy based on it, the potential of various optimization approaches can be investigated and evaluated within an acceptable framework in terms of both time and costs by using sensible laboratory tests.

From Da Vinci to modern tribometry 4.0; requirements for new tribometry 4.0-compatible test benches

Application-oriented tribological testing technology (tribometry) is a decisive development tool on the way to a high-performance product. Based on the tribological system analysis and the test strategy based on it, the potential of various optimization approaches can be investigated and evaluated within an acceptable framework in terms of both time and costs through the use of meaningful laboratory tests.

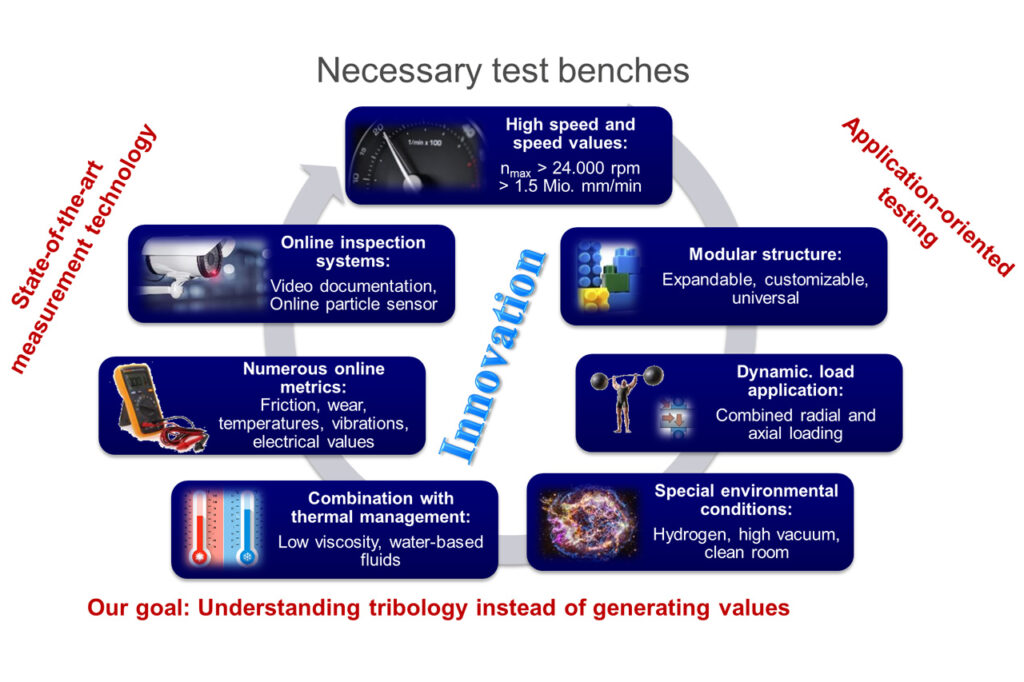

However, the current disruptive developments in many areas of automotive and mechanical engineering require completely new test benches, test methods and evaluation approaches that are adapted to the new requirements. One example is the requirements arising in the field of electric drive technology for vehicles. On the one hand, electrical parameters, such as impedance measurement technology, are moving into focus here for the investigation of electrical interactions in frictional contact. On the other hand, there are load collectives in the application for which there is not yet a broad wealth of experience in the form of standardized test benches or test standards. This lack of experience, coupled with the high development pressure that exists in e-mobility, means that newly developed tests and test benches must provide a full range of measurement data and a high degree of measurement data traceability from the outset in order to provide targeted support for research and development.

Another driver of innovation is sustainability requirements, which are leading to a focus on energy efficiency and the need to replace known chemicals and materials. Whether chromium or PFAS, replacements must be found quickly, as relevant legislation can change within a very short time.

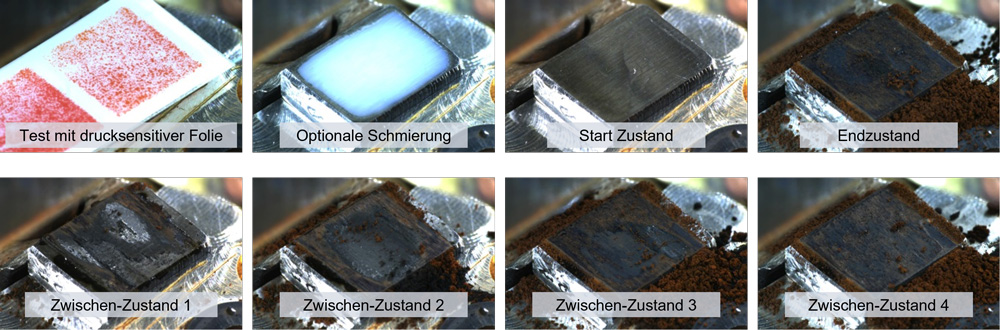

As a test bench developer and R&D service provider in tribology and lubrication technology, TEMa drives the further development of modern testing methods – both in publicly funded research projects and in industry-related contract developments. Our focus is always on the practical simulation of complex tribological systems. Our current work includes topics such as test methods for high-speed applications, methods for investigating grease degradation and its influence on friction conditions, the investigation of electrical properties of lubricants, the analysis of structure-borne noise emissions as early signals for structural changes in the friction partners or feature engineering and the in-situ image acquisition of friction partners for machine learning-based classification of wear patterns.

The aim is an application-oriented, data-driven tribology that goes beyond individual characteristic values and enables a deep understanding of dynamic interactions in the tribological system. Test benches are developing into digital platforms that combine flexible test planning, networked data collection and simulation-based analyses.

Ultimately, we want to simulate tribological systems in the laboratory in an application-oriented manner, understand interrelationships and interactions – not simply generate characteristic values.