Fretting Test Bench

Precise Analysis of Tribochemical Reactions

The BigFret fretting test bench offers you the possibility to analyse tribochemical reactions, also known as fretting corrosion or tribo-oxidation, with the highest precision. The test rig is specially designed for analysing surface contacts and offers exceptional flexibility to test a wide range of materials and lubricants under realistic conditions.

Precise Microtribology Tests Thanks to Exact Contact Control

Compared to conventional test devices, the BigFret enables reliable and precise adjustment of flat contacts, resulting in a high degree of reproducibility in the test series. The rigid drive train also ensures that even the smallest movements in the micrometre range are precisely controlled, virtually irrespective of the frictional force applied - ideal for detailed tests at micro-ribology level.

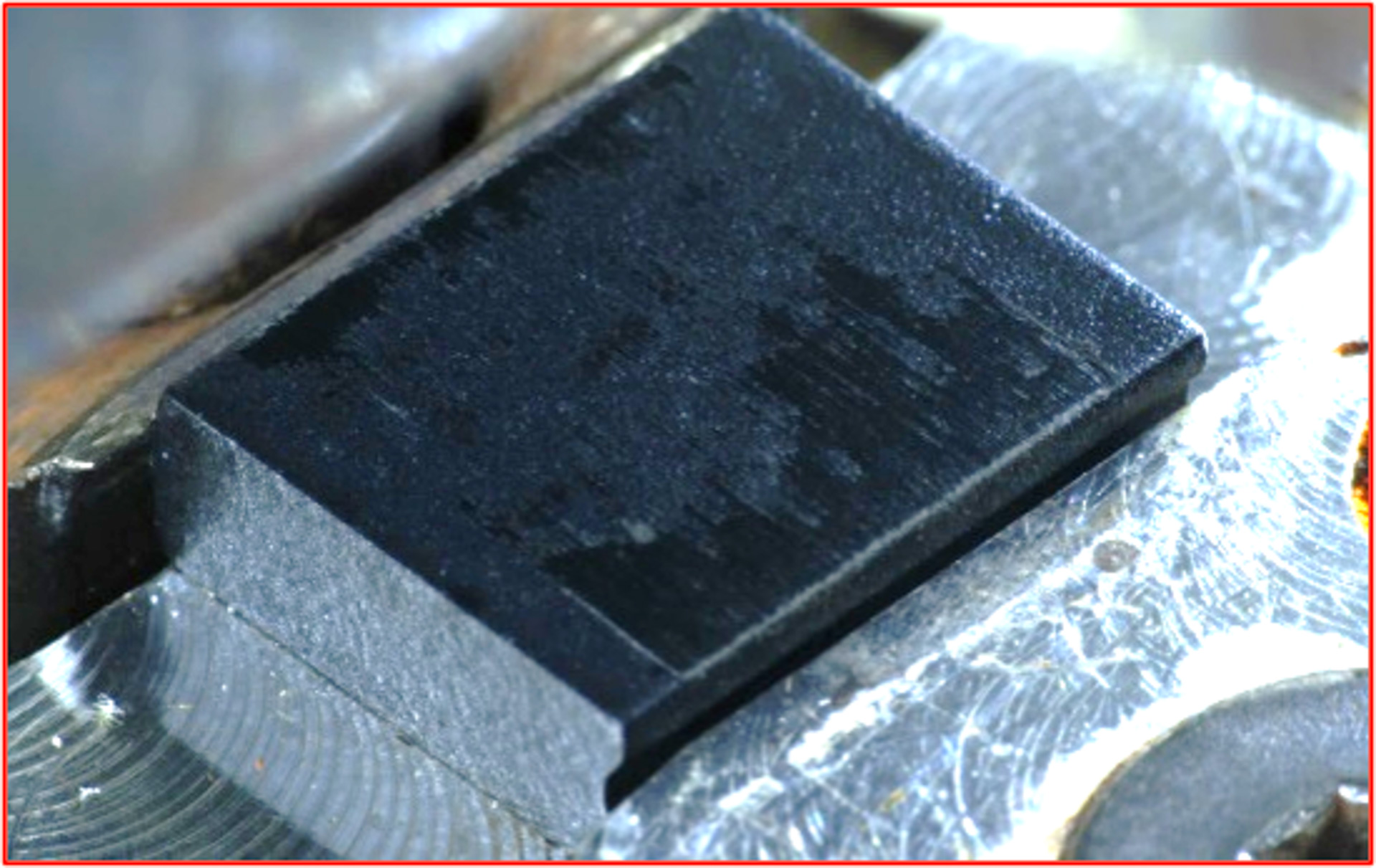

Test specimen at the beginning (top) and at the end of the test series (bottom) with corrosion particles.

Comparison of two bonded coatings in the BigFret.

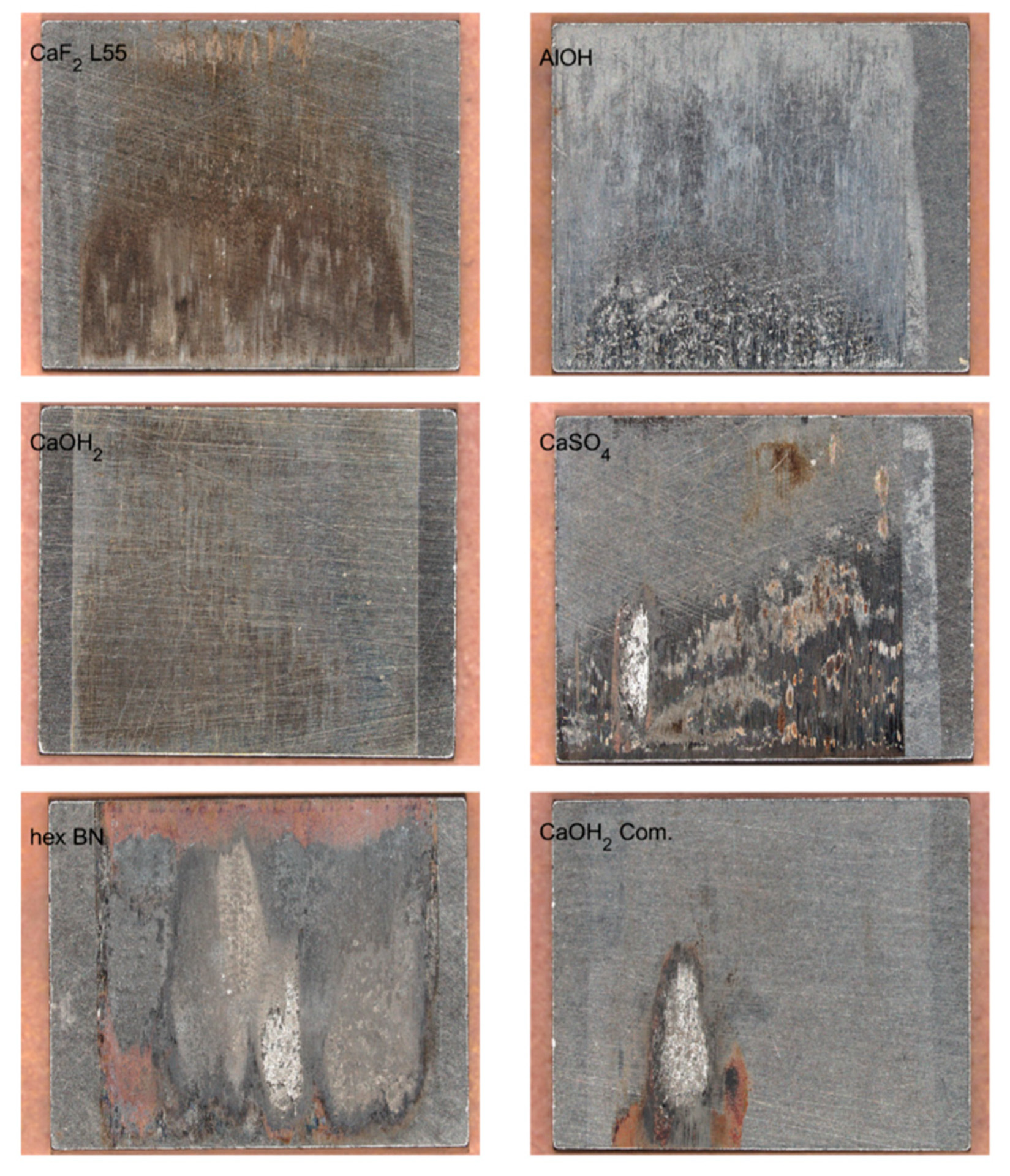

Lubricant Comparison

Test specimens after the test clearly show the different effects of the solid-based lubricants on the surface. Ca(OH)2 leaves a uniform and dense tribological layer that provides strong protection against wear. In comparison, CaF2 shows a very pronounced tribolayer formation, which appears in the form of robust islands on the surface, effectively preventing fretting wear. CaSO4 forms smaller but still well distributed tribolayers that prevent mild abrasion but are not able to form as stable a layer as Ca(OH)2 or CaF2. These differences illustrate how the choice of lubricant influences wear behaviour and the formation of tribological layers on the surface.