High-Speed-Bearing-Tester

High-Speed Bearing Testing for the Future of E-Mobility

The HSBT makes it possible to realistically simulate the demanding operating conditions of modern electrified drivetrains (e-mobility). By using axially braced test bearings, both oscillating vibration loads (from +/- 0.1° to +/- 3°) and extremely high speeds (up to 24,000 rpm) can be simulated alternately. This allows a detailed investigation of the effects of micro-movements and vibrations on the service life of rolling bearings.

1: Frontal view

2: Test sleeve

3: CAD section of test sleeve

4: Standstill marking

Experiment No. 1

The pictures show how the shaker and rotary drives on the HSBT can be used to pre-damage or intermittently load bearings. The top image shows a standstill marking before a subsequent continuous run, the image below after several rotation cycles.

Test No. 2

Lubricant differentiation is very simple due to the free load and wide measurement data acquisition. Above you can see a bearing that shows hardly any damage after vibration and overrolling cycles, compared to a bearing that shows significant standstill marking and surface disintegration.

The two plotted tests are speed increase runs that were run up to an acceleration cut-off. The red grease reaches the cut-off significantly faster and is at an increased vibration level up to the time of switch-off.

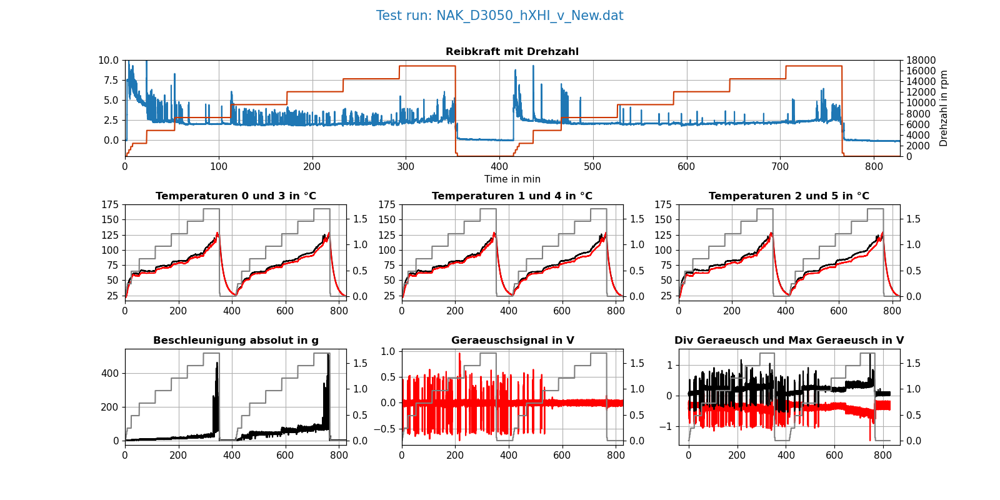

Examples of measurement records from two tests. The top line shows the rotational speed in red and the friction force in blue.