Multi-Station Oscillation Test Rig

Double the View, Double the Insight!

The Oszilla Zero allows you to analyze tribological processes under oscillating contact conditions with unmatched precision.

Developed specifically for the study of dynamic load profiles, its extended frequency and stroke range opens the door to realistic testing scenarios across new frontiers in lubricant, material, and coating development.

In the video:

Frictional force-, normal force- and wear-measurements of both test heads top left, friction-hysteresis top right, time lapse insitu microscopy of upper and lower sample of both test heads.

High-Precision Oscillation Tests for Real-World Applications

Thanks to its innovative, symmetrical dual-chamber architecture, the effects of moving masses during oscillation are effectively compensated. This leads to a reduction in vibration transmission and unwanted inertial forces – enabling more precise force and motion transmission as well as increased measurement accuracy.

Whether testing for wear, lubricant film stability, or material transfer – even at high frequencies and large strokes, the system operates with the highest precision and reproducibility.

The robust drive system controls movements down to the sub-micrometer range, virtually unaffected by the acting frictional forces.

Frictional behaviour comparison of various plastics.

PC vs PC: after testing in the right chamber has seized due to high wear in PC vs PC test, mass is continuously compensated through oscillation without normal force.

Oszilla Ensures Full Transparency.

Our high-precision camera system operates with a motorized swing-in mirror, allowing us to capture both the lower base plate and the upper specimen in real time. This setup enables the simultaneous documentation of wear progression on both contact partners with identical optical resolution.

The integration of optical image analysis significantly enhances the understanding of tribological processes by correlating mechanical measurement data with visual wear development. It allows us to precisely document and quantify wear mechanisms over time—without interrupting the test.

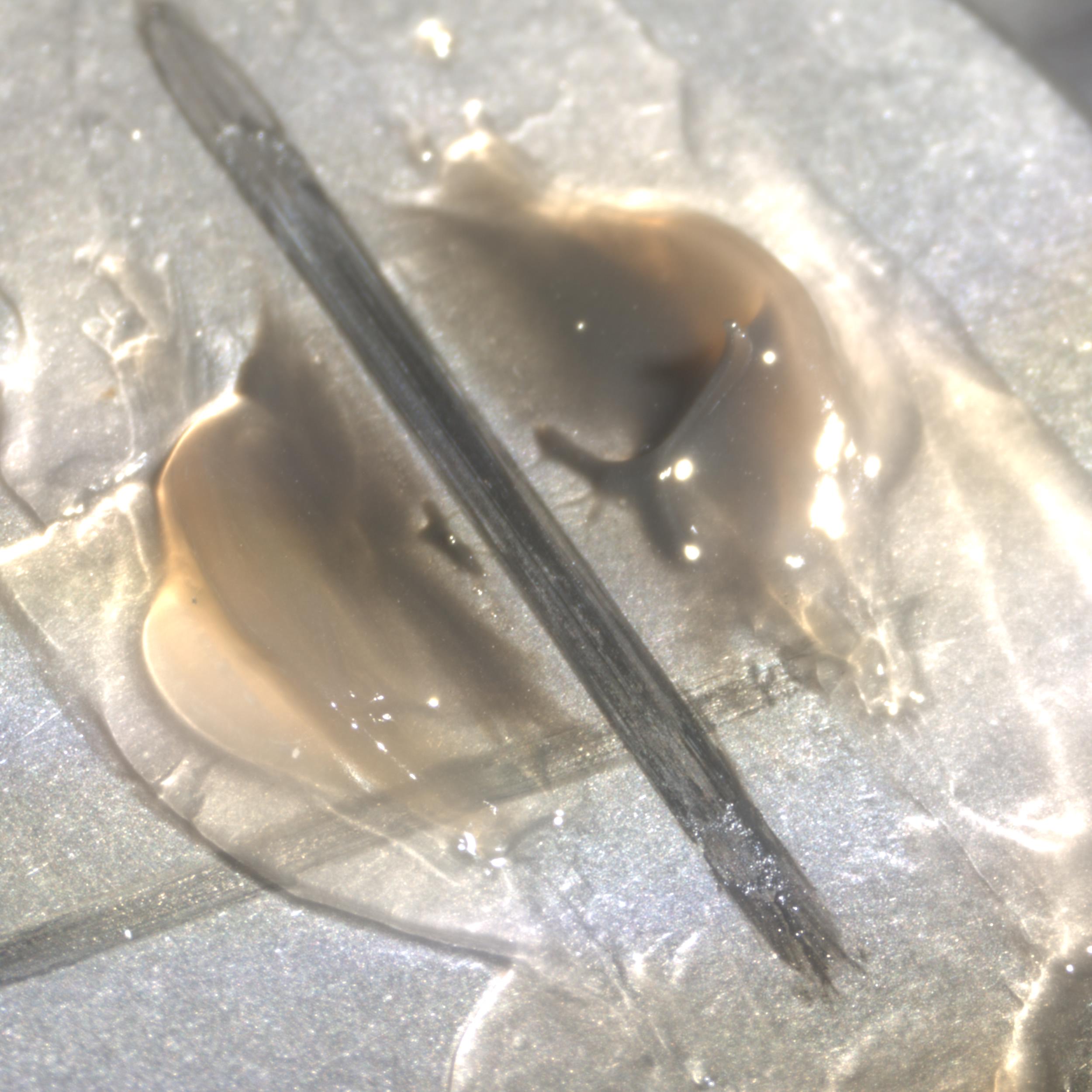

In-situ microscopy of a grease-lubricated oscillating sliding wear test on a ball-on-plate system

Standard Conformity and Beyond

With its broad parameterization capabilities, the Oszilla Zero is ideal for conducting a wide range of standard tests – inherently in duplicate.

DIN-Standards

DIN 51834-2: Bestimmung von Reibungs- und Verschleißmessgrößen für Schmieröle

E DIN 51834-3: Bestimmung des tribologischen Verhaltens von Werkstoffen im Zusammenwirken mit Schmierstoffen

E DIN 51834-4: Prüfung der tribologischen Gebrauchstauglichkeit von Getriebe-/Hydraulikflüssigkeiten

DIN 51834-5: Quantifizierung der reibungsbedingten Geräuschentwicklung von Bremsflüssigkeiten

DIN E 51834-6: Wear Brake Fluids

DIN E 51834-7: Gear Oil Screening Test

E DIN 51834-8: Tribologische Prüfung von gebundenen Trockenschmierstoffen

E DIN 51834-9: Bestimmung von Reibungs- und Verschleißmessgrößen für fettgeschmierte Kunststoffgleitpaarungen

ASTM-Standards

ASTM D6425-23: Measuring Friction and Wear of Extreme Pressure Lubricating Oils

ASTM D5706-05: Measuring Friction and Wear Properties of Lubricating Greases

ASTM D7564-24: Determining Fretting Wear Resistance of Lubricating Greases

ASTM D7420-23: Determining Tribomechanical Properties of Grease Lubricated Plastic

ASTM D8317-23: Measuring Friction and Wear Properties Under Rolling Motion Greases

ASTM D7421-23: Determining Extreme Pressure Properties of Lubricating Oils

International Standards

ISO 19291:2016: Tribologische Prüfung in einem translatorischen Oszillations-Prüfgerät

DIN ISO 12156-1: Dieselkraftstoff-Methode zur Bestimmung der Schmierfähigkeit

EN 1071: Reciprocating Wear Test for Ceramic Coatings