Rotational Tribometer

Turning in Circles - with Top Performance

Our RoTri is a sophisticated testing device that has been specially developed for analysing and simulating friction and wear processes under a wide range of conditions. It enables the precise analysis of sliding stresses - both continuous and oscillating - under axial loads. Thanks to an intelligent adapter system, almost all test specimen geometries can be used on this universal tribometer, making it a flexible solution for a wide range of applications.

1: Lubricant pot

2: Sketch view with safety door

3: Adapter with gimbal

4: Example of sub-sample holder

RoTri-8000: Flexible Test Platform for Rotationally Stressed Systems

The RoTri-8000 allows infinitely variable control of load, speed and temperature in the test at up to 8,000 newtons of normal force. The fine, flexible control makes it possible to realise a large number of standard tests for rotationally stressed systems, as well as a wide range of component tests, from axial plain bearings to pump running surface tests.

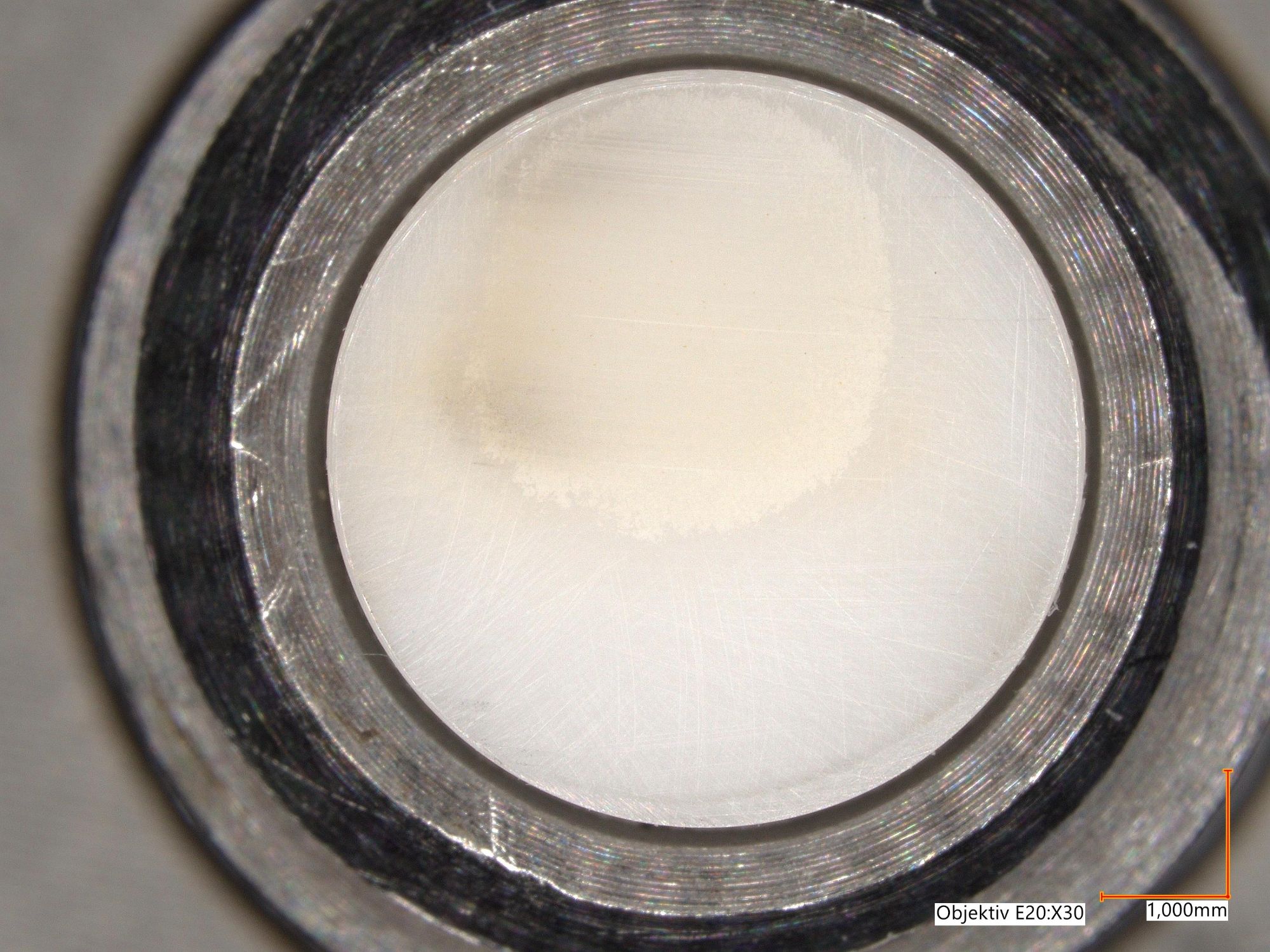

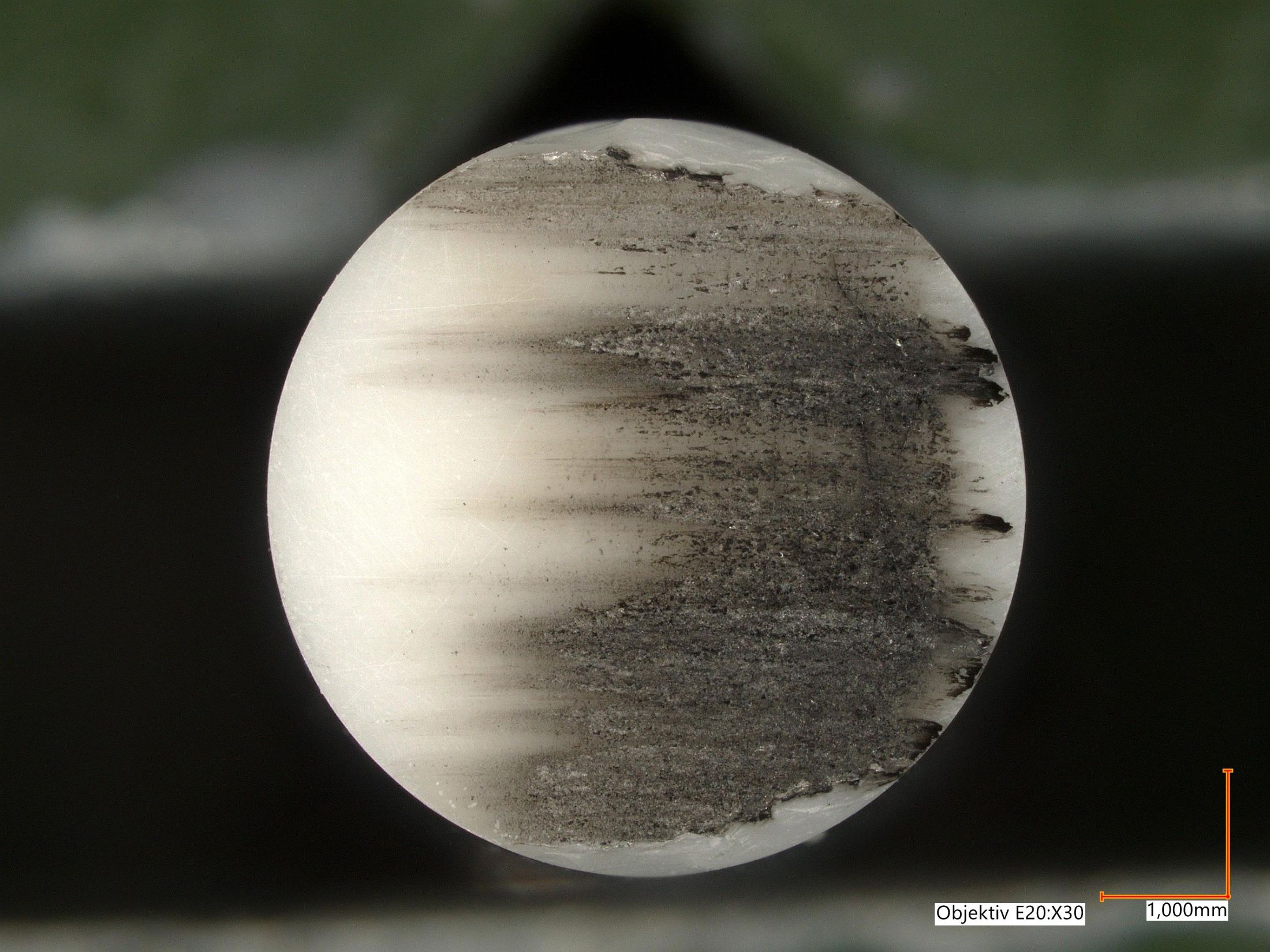

Here you can see ceramic pins running against steel discs in splash lubrication. It is easy to see how, in ‘good lubrication’, only minor chipping on the pin and faint traces of disc wear are visible. In the ‘poor lubrication’, large chippings are visible on the pin.

Extract from a comparative study of different coatings in pin-on-disc load ramping. Contact current shows good differences in running-in and hydrodynamic behaviour, while frictional torque enables simple differentiation as the load increases.

In the pin-on-disc arrangement, the Ro-Tri is ideal for testing coating durability. Figures 1 and 2, for example, show a coated disc before and after the test (Figure 2 with significant coating loss). Figures 3 and 4 show the before and after of a much more resistant coating. Figures 5 and 6 are comparative images of an uncoated pin and disc.