The development of lubricants is characterised by so-called release tests or the attainment of certain laboratory markers in accordance with standardised tests, usually defined in norms.

Vane pumps have historically stood out as a means of testing due to their constant mechanical load and widespread use in real applications and are an integral part of oil and additive research.

The (formerly Vickers) V104c and the Eaton 35VQ25 are particularly widespread. Basically, these are vane pumps that run against the resistance of a pressure relief valve. The fluid in the race/vane cell gap is subjected to mechanical stress due to the pressure applied and thermal stress due to the increase in friction.

Automatic 2-Tank Test Stand V104c for Standard-Compliant Tests According to DIN and ASTM

Our V104c test bench is an automatically convertible 2-tank system that allows you to easily switch back and forth between the design requirements of the DIN and ASTM standards so that both can be mapped in full compliance with the standards. It also provides valuable insights into the pump system, as measured variables such as the frictional torque and filter pre-pressure are recorded.

Good Fluid: Microscopy of Vane Cells (Top & Centre) and Race (Bottom).

Slight signs of abrasion on the edges of the vane cells and the barrel ring are the only damage after testing. The fluid passes the test.

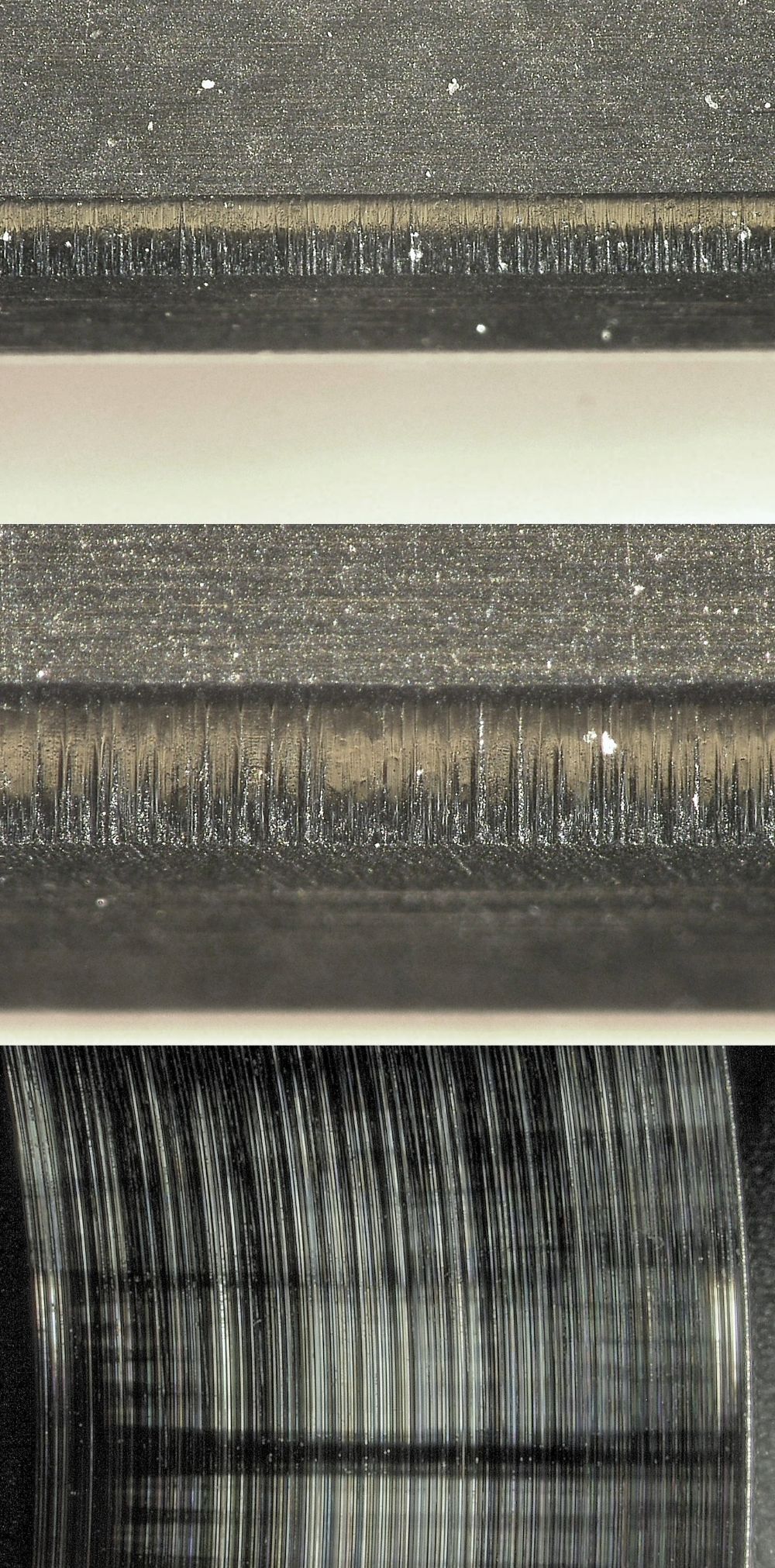

Bad fluid: Microscopy of Vane Cells (Top & Centre) and Race (Bottom).

Here the fluid performs quite poorly in the test - pronounced cavitation damage on the impeller ring and vane cells leads to increased mass loss - the fluid fails the test.;

Test data from a standardised test. Here, fluid is pumped at constant pressure for 100 hours, or until the flow rate falls below a certain level. Over the first 24 hours, a kind of run-in seems to take place, indicated by friction torque fluctuation and strong temperature readjustment. Also interesting is the linear increase in P3 over the test as an indication of filter fouling.

35VQ25 Test Bench

We also offer you the right test bench for other oil release tests. For example, our 35VQ25 for test standard D6973 - 14 based on the 35VQ25 Eaton pump.